Visual Quality Control of Weld

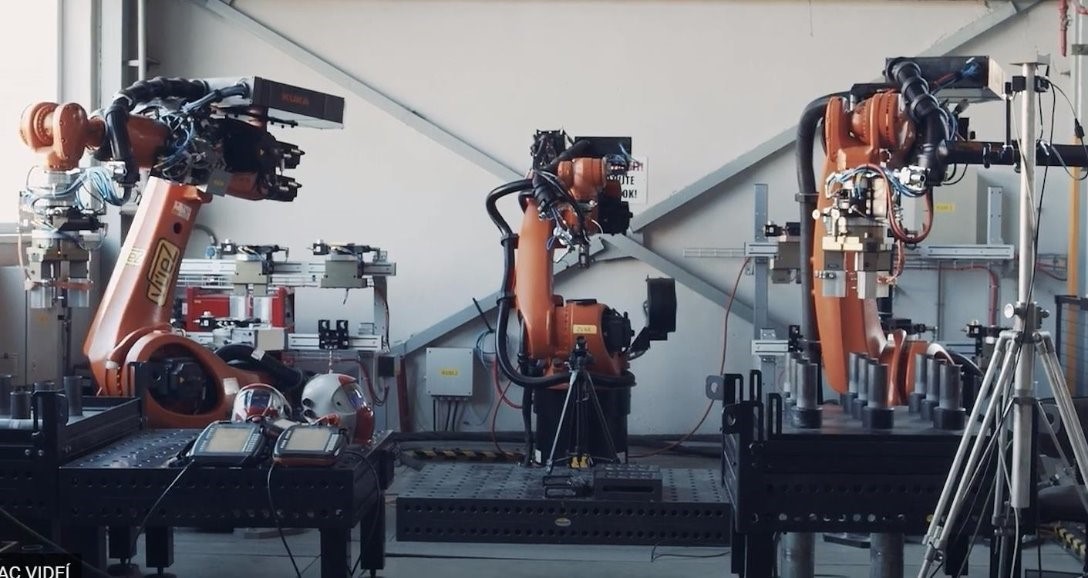

The AiA Visual Quality Control of Welds project leverages computer vision to automate the inspection of welds, ensuring consistent and accurate detection of defects in real-time video feeds. The project utilizes two AI-powered image detection models to support quality control processes by identifying and categorizing specific weld issues.

The first AI model is designed to distinguish between acceptable („OK“) and defective („NOK“) welds, achieving a high success rate of 98.6%. This reliable detection capability lets manufacturers quickly identify faulty products, ensuring that only high-quality welds proceed through production.

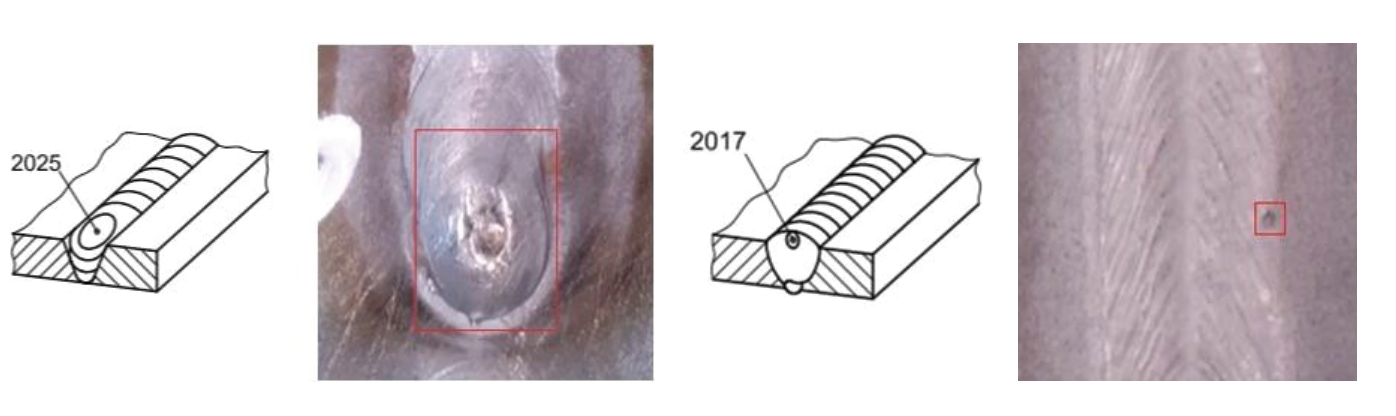

The second AI model further categorizes defective welds by detecting seven specific types of weld issues. The success rate of this model varies from 50% to 81%, depending on the robustness and quantity of labeled data available for each defect type. As more labeled data becomes available, we anticipate continued improvement in the model’s performance, enhancing its utility for precise defect classification.